In today’s fast-paced world of technology, efficiency is key. Whether you’re in manufacturing, logistics, or any other industry that relies on conveyor belts and filters, having high-performance equipment can make all the difference.

The Importance of High-Performance Conveyor Belts

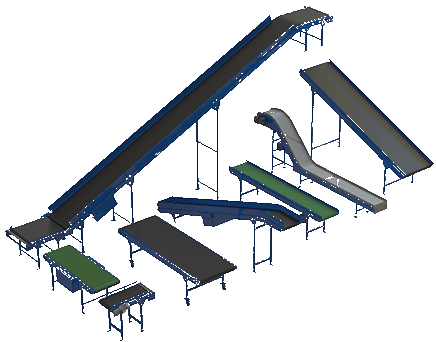

Conveyor belts are the backbone of many industries, helping to move products and materials seamlessly from one point to another. High-performance conveyor belts are designed to handle heavy loads, resist wear and tear, and operate smoothly and efficiently. These belts are essential for maintaining productivity and reducing downtime in any production facility.

When choosing a high-performance conveyor belt, it’s important to consider factors such as material composition, strength, and durability. Look for belts that are made from quality materials like rubber, PVC, or nylon, and have a high tensile strength to withstand heavy loads. Additionally, belts with low friction coatings can help to reduce wear and tear and extend the life of the belt.

Benefits of High-Performance Filters

Filters are another essential component of many industrial processes, helping to remove impurities and contaminants from liquids and gases. High-performance filters are designed to offer superior filtration efficiency, optimal flow rates, and long-lasting durability. These filters are essential for maintaining product quality and ensuring the smooth operation of machinery and equipment.

High-performance filters come in a variety of types, including air filters, oil filters, and water filters. Air filters are essential for maintaining air quality in industrial environments, while oil filters help to remove contaminants from lubricants and prolong the life of machinery. Water filters are essential for removing impurities from water used in industrial processes, ensuring product quality and reducing the risk of equipment damage.

Choosing the Right Equipment for Your Needs

When selecting high-performance conveyor belts and filters for your facility, it’s important to consider your specific needs and requirements. Think about the types of materials you will be handling, the level of wear and tear your equipment will be subjected to, and the flow rates required for your processes. Consult with a knowledgeable supplier or manufacturer to ensure you select the right equipment for your needs.

Investing in high-performance conveyor belts and filters can have a significant impact on the efficiency and productivity of your operation. By choosing quality equipment that is designed to withstand heavy loads, resist wear and tear, and operate smoothly, you can minimize downtime, reduce maintenance costs, and maximize overall efficiency.

Conclusion

High-performance conveyor belts and filters are essential components of many industrial processes, helping to maintain efficiency, productivity, and product quality. By investing in quality equipment that is designed to withstand heavy loads, resist wear and tear, and operate smoothly, you can ensure the smooth operation of your facility and achieve optimal performance.

When choosing high-performance conveyor belts and filters, consider factors such as material composition, strength, durability, and filtration efficiency. Consult with a knowledgeable supplier to ensure you select the right equipment for your specific needs. With the right equipment in place, you can maximize efficiency and productivity in your industrial operation.